TECHNICAL PARAMETERS |

DETAILS |

|---|---|

| WIRING «FROM LEFT TO RIGHT» | 1: Ex+, 2: Sig+, 3: Ex-, 4: Sig- |

| SENSOR DIMENSIONS | 25mm X 25mm X 5mm |

| RATED CAPACITY | SAME AS YOUR STRUCTURE «UNLIMITED CAPACITY» |

| TOTAL ERROR | FROM .5% TO 3% «BASED ON THE ACTUAL STRUCTURE» |

| THERMAL OUTPUT | 0.5 μ m/m DEGREES C (-1) |

| ZERO BALANCE | + OR – 1% OF FULL SCALE |

| INPUT | 350 OHMS + OR – 3 OHMS |

| OUTPUT | 350 OHMS + OR – 3 OHMS |

| GAUGE FACTOR | 2.12 ± 0.5% |

| ACTUAL GRID SIZE OF EACH STRAIN GAUGE | 3mm X 3mm |

| INSULATION IMPEDANCE | LESS THAN 5000 MEGA OHMS |

| OPERATING TEMPERATURE RANGE | -40 TO +60 DEGREES C |

| MAXIMUM SAFE OVERLOAD | BASED ON THE ACTUAL STRUCTURE |

| UNLIMITED OVERLOAD | BASED ON THE ACTUAL STRUCTURE |

| EXCITATION | FROM 1 TO 12 VOLTS DC |

| MAXIMUM EXCITATION | 15 VOLTS DC |

| PROTECTIVE COVER MATERIAL | STAINLESS STEEL COVER «OPTIONAL» |

| CABLE LENGTH | BASED ON THE CUSTOMER’S REQUEST |

| CABLE TYPE | BASED ON THE CUSTOMER’S REQUEST |

TECHNICAL PARAMETERS |

DETAILS |

|---|---|

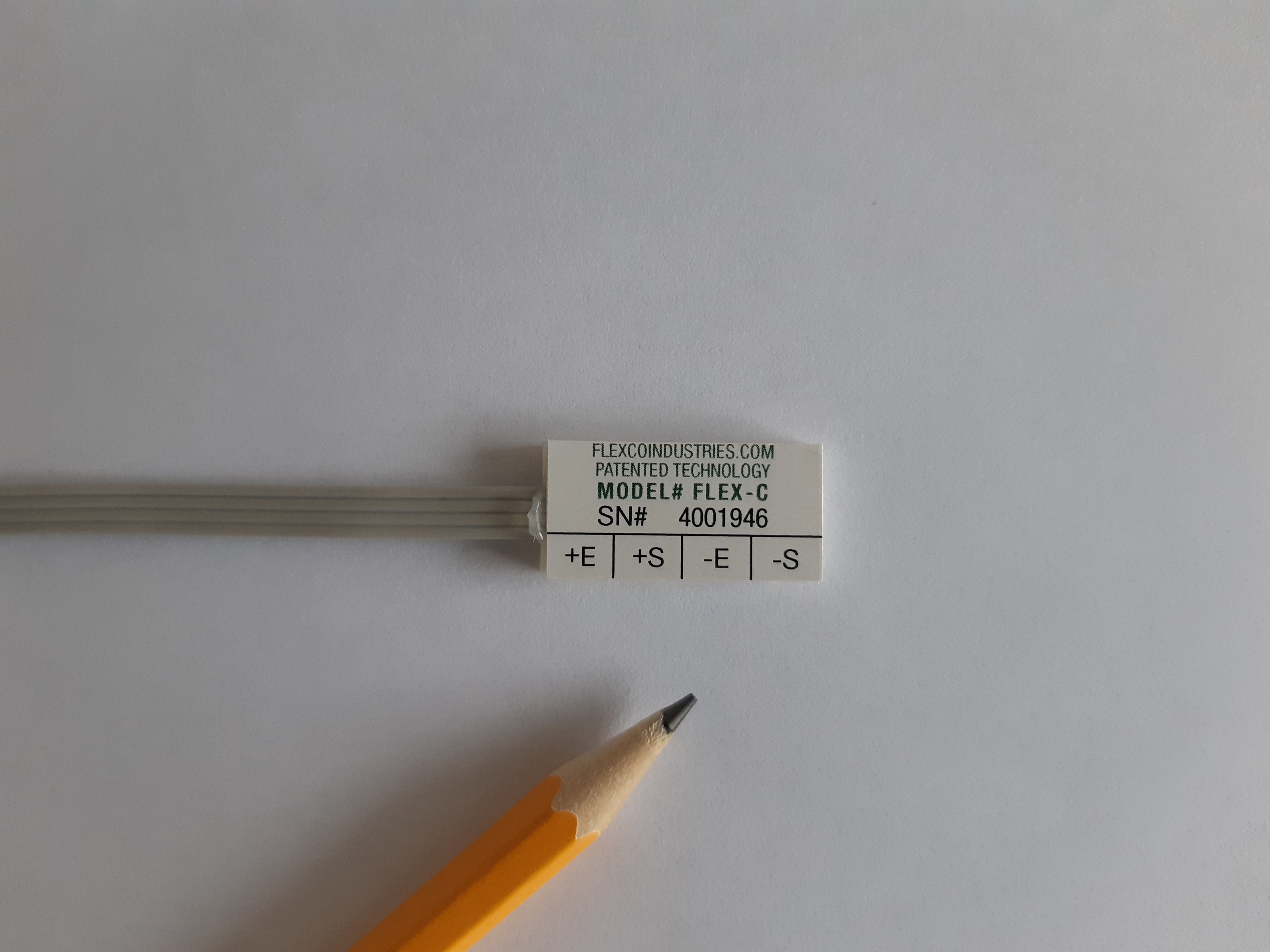

| WIRING «FROM LEFT TO RIGHT» | 1: Ex+, 2: Sig+, 3: Ex-, 4: Sig- |

| SENSOR DIMENSIONS | 25mm X 13mm X 5mm |

| RATED CAPACITY | SAME AS YOUR STRUCTURE «UNLIMITED CAPACITY» |

| TOTAL ERROR | FROM .5% TO 3% «BASED ON THE ACTUAL STRUCTURE» |

| THERMAL OUTPUT | 0.5 μ m/m DEGREES C (-1) |

| ZERO BALANCE | + OR – 1% OF FULL SCALE |

| INPUT | 1000 OHMS + OR – 3 OHMS |

| OUTPUT | 1000 OHMS + OR – 3 OHMS |

| GAUGE FACTOR | 2.12 ± 0.5% |

| ACTUAL GRID SIZE OF EACH STRAIN GAUGE | 4mm X 4mm |

| INSULATION IMPEDANCE | LESS THAN 5000 MEGA OHMS |

| OPERATING TEMPERATURE RANGE | -40 TO +60 DEGREES C |

| MAXIMUM SAFE OVERLOAD | BASED ON THE ACTUAL STRUCTURE |

| UNLIMITED OVERLOAD | BASED ON THE ACTUAL STRUCTURE |

| EXCITATION | FROM 1 TO 12 VOLTS DC |

| MAXIMUM EXCITATION | 15 VOLTS DC |

| PROTECTIVE COVER MATERIAL | STAINLESS STEEL COVER «OPTIONAL» |

| CABLE LENGTH | BASED ON THE CUSTOMER’S REQUEST |

| CABLE TYPE | BASED ON THE CUSTOMER’S REQUEST |

Strain Gauge/Gage Sensors

Custom Flexco Patented Sensors can be embedded with different types and configurations of strain gauges to allow the operator a hassle free installation, no matter the requirement.

Available options:

-Custom type/configuration of gauge: Full Wheatstone Bridge, Quarter Bridge, Half Bridge, Rosette, Concrete Gauge…)

-Custom cable types and lengths

-Custom thicknesses and sizes

-Custom housings and connector plugs